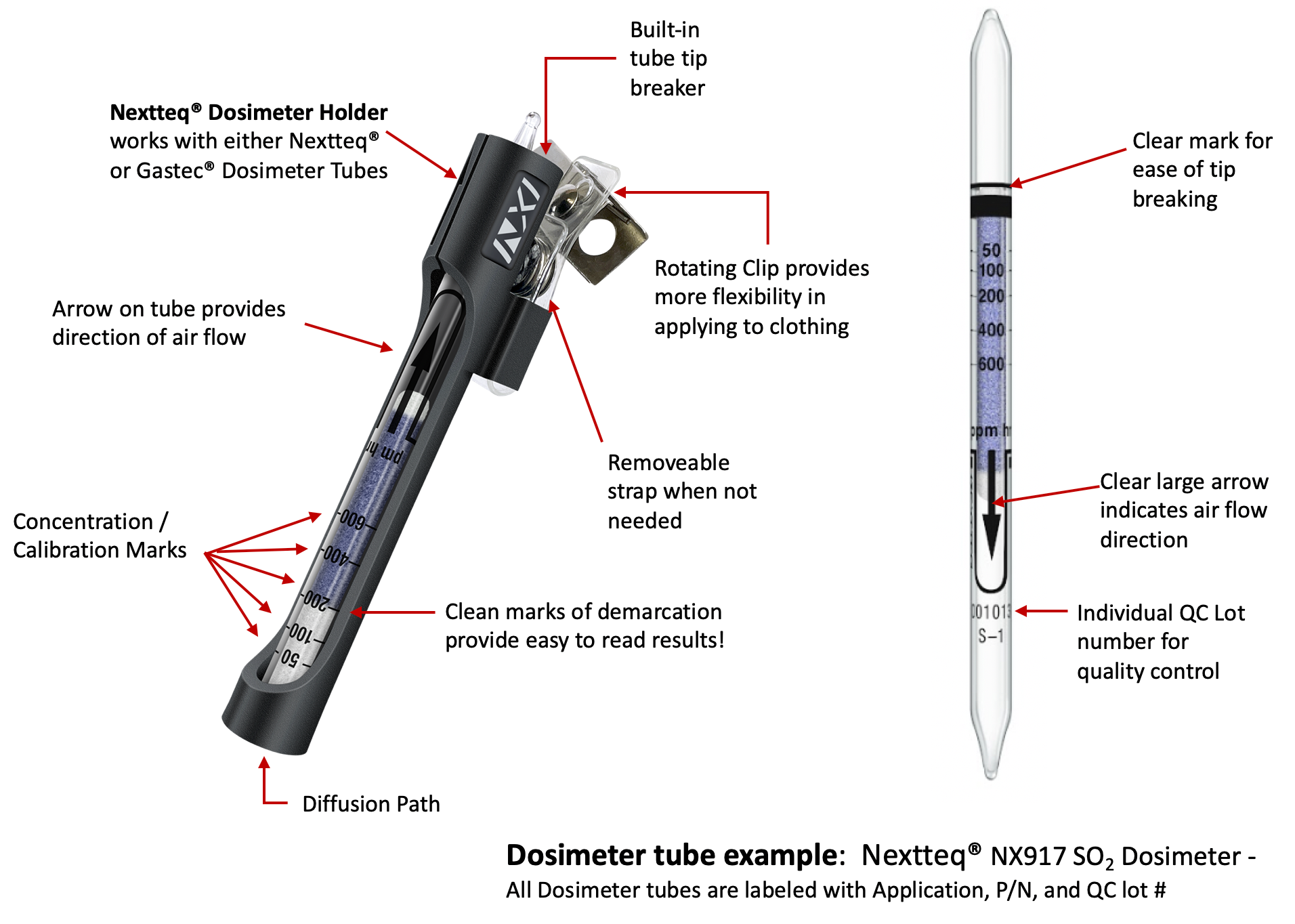

Nextteq® provides quality dosimeter tubes for TWA monitoring - Over 40 applications available - Sampling Made Simple.

Example of Dosimeter Tube Usage - SO₂

SO₂ is used in the wine industry for its preservative and antimicrobial properties. Its primary roles include preventing wine spoilage, inhibiting the introduction of unwanted bacteria and wild yeasts, and stabilizing the wines to maintain their color, flavor and aroma. It is utilized during various stages of the wine making process such as during fruit crushing, fermentation, or bottling. A dosimeter tube can be used as both a personal monitor or an area monitor to assure adequate amounts of SO₂ were applied for a particular process and/or to prevent potential overexposure to workers during the SO₂ applications.

Ordering Information

Dosimeter Tube Holders - 3/bag - P/N 90460-3

| Substance to be measured | Tube Number | Brand Nextteq (NXI) Gastec (G) | Tube Name | Measuring range | Scale range |

|---|---|---|---|---|---|

| Acetaldehyde | 151D | G | Acetone | 4-1200 | |

| 152D | G | Methyl ethyl ketone | 1.2-360 | ||

| 91D | G | Formaldehyde | 0.1-20 | 1-20ppm・hr | |

| Acetic acid | 81D | G | Acetic acid | 0.5-100 | 5-100ppm・hr |

| Acetic anhydride | 81D | G | Acetic acid | 0.3-60 | |

| Acetone | 151D | G | Acetone | 5-1500 | 50-1500ppm・hr |

| 152D | G | Methyl ethyl ketone | 1.4-420 | ||

| Ammonia | 3D | G | Ammonia | 2.5-1000 | 25-500ppm・hr |

| 3DL | G | Ammonia | 0.1-10 | 1-10ppm・hr | |

| Benzene | 122DL | G | Toluene | 2.4-600 | |

| 1,3-Butadiene | 174D | G | 1,3-Butadiene | 1.3-200 | 10-200ppm・hr |

| Carbon dioxide | 2D | G | Carbon dioxide | 0.02-12% | 0.2-6.0%・hr |

| Carbon monoxide | 1D | G | Carbon monoxide | 1.04-2000 | 50-1000ppm・hr |

| 1DL | G | Carbon monoxide | 0.4-400 | 10-200ppm・hr | |

| Chlorine | 132D | G | Trichloroethylene | 2.4-240 | |

| 8D | G | Chlorine | 0.08-100 | 2-50ppm・hr | |

| Cumene | 122DL | G | Toluene | 3.4-850 | |

| trans-1,2-Dichloroethylene | 174D | G | 1,3-Butadiene | 3.8-600 | |

| 1,2-Dichloroethylene | 132D | G | Trichloroethylene | 6-600 | |

| Dimethylamine | 3D | G | Ammonia | 1.9-750 | |

| N,N-Dimethylethylamine | 3D | G | Ammonia | 4-1600 | |

| Ethanol | 112D | G | Ethanol | 100-25000 | 1000-25000ppm・hr |

| Ethyl benzene | 122DL | G | Toluene | 2.8-700 | |

| Ethylene | 174D | G | 1,3-Butadiene | 1.5-240 | |

| Formaldehyde | 91D | G | Formaldehyde | 0.1-20 | 1-20ppm・hr |

| Formic acid | 81D | G | Acetic acid | 0.55-110 | |

| Furfural | 91D | G | Formaldehyde | 0.3-60 | |

| Hydrazine | 3D | G | Ammonia | 1.6-650 | |

| Hydrogen chloride | 132D | G | Trichloroethylene | 1.8-180 | |

| 14D | G | Hydrogen chloride | 1-100 | 10-100ppm・hr | |

| 17D | G | Hydrogen fluoride | 0.4-40 | ||

| Hydrogen cyanide | 12D | G | Hydrogen cyanide | 1-200 | 10-200ppm・hr |

| Hydrogen fluoride | 14D | G | Hydrogen chloride | 2.5-250 | |

| 17D | G | Hydrogen fluoride | 1-100 | 10-100ppm・hr | |

| Hydrogen peroxide | 32D | G | Hydrogen peroxide | 0.5-40 | 5-40ppm・hr |

| Hydrogen sulfide | 4D | G | Hydrogen sulfide | 0.2-200 | 10-200ppm・hr |

| Isoprene | 174D | G | 1,3-Butadiene | 2.5-400 | |

| Methyl ethyl ketone | 151D | G | Acetone | 6.5-1950 | |

| 152D | G | Methyl ethyl ketone | 2-600 | 20-600ppm・hr | |

| 91D | G | Formaldehyde | 0.125-25 | ||

| Methyl isobutyl ketone | 151D | G | Acetone | 11.5-3450 | |

| 152D | G | Methyl ethyl ketone | 4-1200 | ||

| Methylamine | 3DL | G | Ammonia | 0.19-19 | |

| Nitric acid | 14D | G | Hydrogen chloride | 0.8-80 | |

| 17D | G | Hydrogen fluoride | 0.32-32 | ||

| Nitrogen dioxide | 9D | G | Nitrogen dioxide | 0.1-30 | 1-30ppm・hr |

| 9DL | G | Nitrogen dioxide | 0.01-3.0 | (0.1)-3.0ppm・hr | |

| Styrene | 122DL | G | Toluene | 26-6500 | |

| Sulfur dioxide | NX917 | (NXI) | Sulfur dioxide | 10-600 | 50-600ppm・hr |

| 5DH | G | Sulfur dioxide | 10-600 | 50-600ppm・hr | |

| 5D | G | Sulfur dioxide | 0.2-100 | 2-100ppm・hr | |

| Tetrachloroethylene | 133D | G | Tetrachloroethylene | 3-150 | 25-150ppm・hr |

| 132D | G | Trichloroethylene | 1.5-150 | ||

| Toluene | 122DL | G | Toluene | 2-500 | 20-500ppm・hr |

| Trichloroethylene | 132D | G | Trichloroethylene | 3-300 | 25-300ppm・hr |

| Triethylamine | 3D | G | Ammonia | 5.3-2100 | |

| Trimethylamine | 3DL | G | Ammonia | 0.23-23 | |

| Vinyl chloride | 174D | G | 1,3-Butadiene | 1.5-240 | |

| Xylene | 122DL | G | Toluene | 3.4-850 |